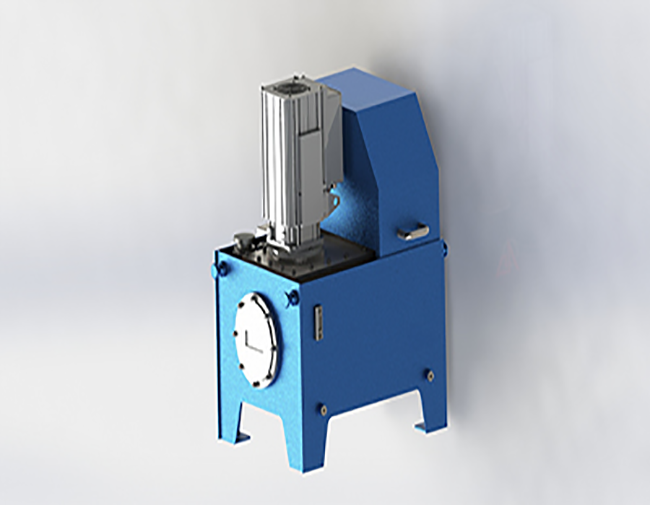

Introduction to servo hydraulic riveting machine

The hydraulic system of the traditional riveting machine uses a three-phase asynchronous motor to drive the oil pump at the rated speed, and the motor is always at a constant speed. When the equipment is in the pressurized and unloaded state, the motor speed is constant, and the excess hydraulic oil flows back to the oil tank through the overflow valve, causing energy waste.

By upgrading the servo of the traditional riveting machine, energy saving and consumption reduction, green forging, and clean production are achieved, which can improve product quality, reduce pollution, reduce costs, and improve benefits for enterprises.

Servo hydraulic riveting machine system principle:

The electro-hydraulic servo system integrates servo technology and hydraulic technology, and adopts the combination of internal gear pump and integrated synchronous servo motor. Intelligently control the speed of the servo motor to achieve the actual pressure and flow required by the equipment.

Advantages of direct drive servo-hydraulic riveting machine:

1. The energy saving effect is obvious, reaching 40-60%.

2. Low noise.

3. The structure is simple, the failure rate is low, the booster cylinder, relief valve, etc. are removed, and the service life of the equipment is prolonged.

4. Energy saving and consumption reduction.