Working principle of flat forging machine

The flat forging machine is an end forging machine for upsetting bars and tubes in the horizontal direction. The flat forging machine has 3 kinds of motion mechanisms. The punch (punch) reciprocates in the horizontal direction. Generally, 4 to 6 die cavities can be set up, which are used for the forming mechanism of the upsetting process such as accumulation, heading, punching, and flanging, and are also the main force-applying mechanism. Movable die: It can be opened and closed upwards, downwards or horizontally to clamp long bars and withstand the upsetting force at the end. Cutting mechanism: used to separate the forging from the long bar. Flat forging machines are all driven by a crank slider mechanism. Due to the large workpiece to be processed, the upsetting force and clamping force are large, the machine needs to have sufficient rigidity to ensure the accuracy of the flat forging.

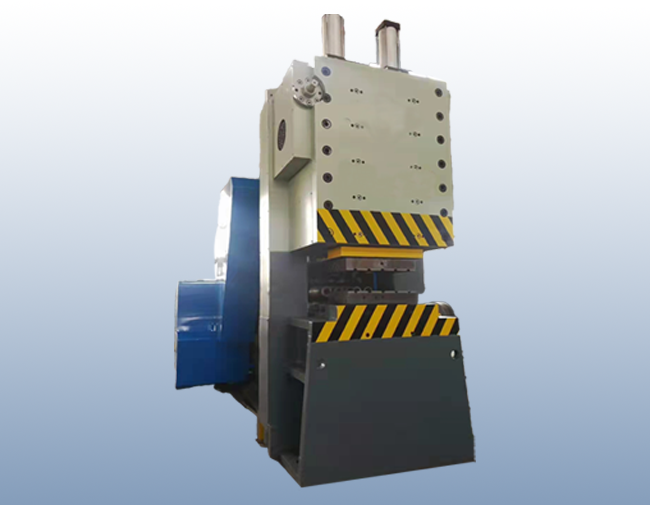

.png)