Introduction of CKH series heavy CNC lathe

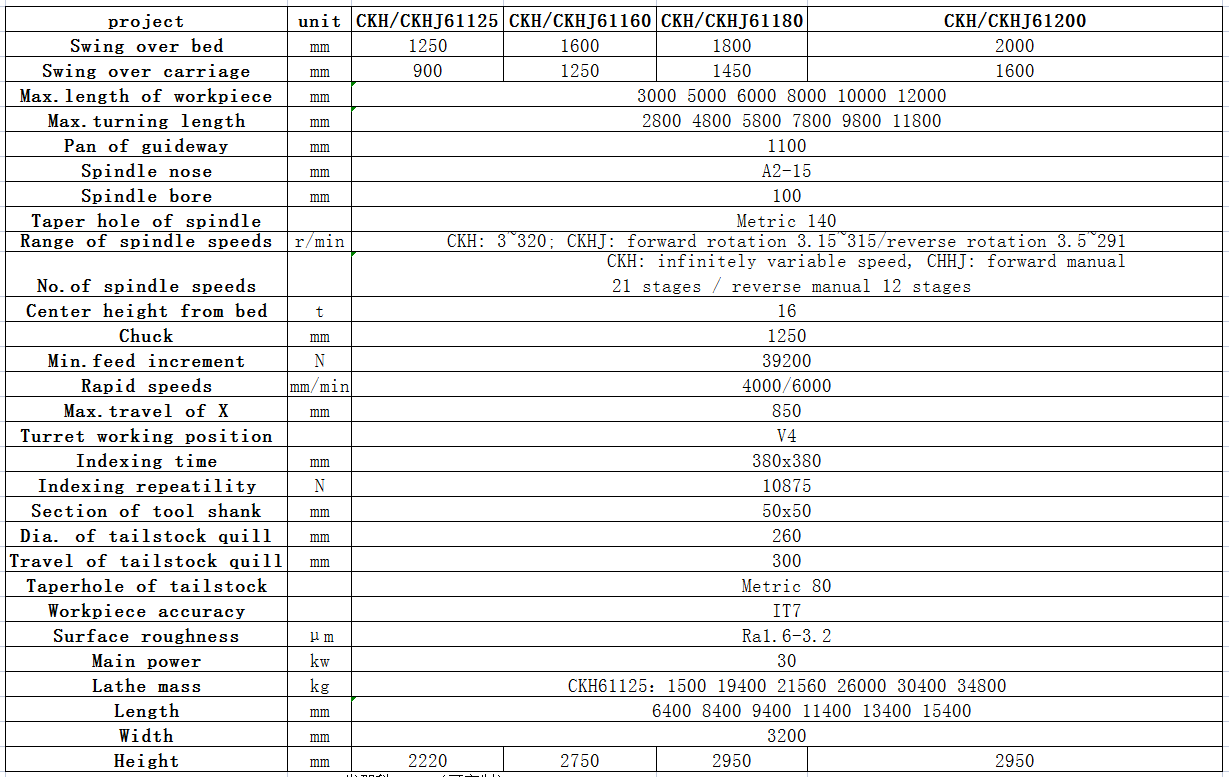

CKH (J) 61125/160/200 series of heavy-duty CNC lathes have semi-closed-loop control function, load-bearing is 16000kgs, the machine tool is versatile, flexible operation, suitable for processing various complicated shapes of shafts, sleeves, disk parts, such as turning the outer cylindrical surface, conical surface, arc surface, end surface, grooving, chamfering, threading, etc., it is the ideal heavy-duty machining equipment.

Main features of CKH series heavy-duty CNC lathe

1. The bed is an integral box-shaped structure, which is made of high-standard cast iron (HT300) in one-time molding casting, and after two aging treatments, the stability is good; the guideway width is 1100mm.

2. Headstock: The structure of the box body is strong, the gears are quenched and precision ground, with high precision, stable operation, and low noise. The diameter of the spindle is large, supported by precision heavy-load bearings for three-point support, and the rotation is stable, it can perform heavy cutting and finish cutting. Automatic forced circulation lubrication makes the transmission system operate flexibly and can effectively cool down. it can also realize step-less speed change and constant linear speed cutting.

3. Feeding: axis-Z sliding guideway are covered with TSF soft belt, which greatly reduces the friction coefficient and improves the servo response performance, axis-X feeding is driven by AC servo motor which is directly connected with the ball screw through the flexible servo coupling, guaranteed high machining accuracy, positioning accuracy, and accuracy retention. Each motion parts are automatically lubricated by a centralized intermittent lubrication system. 1000-6000MM specifications are driven by an AC servo motor via a high-precision planetary reducer Feeding, the specifications above 8000MM are fed by the rack and pinion drive. The machine tool has high positioning accuracy and repeated positioning accuracy.

.png)

.png)

.png)

.png)