Description of Power Hammer for Blacksmith

Power Hammers for blacksmiths (from 15kg to 110kg) are self-contained pneumatic power hammers. The design is based on the time-proven designs of the old European hammers many of which are still in use today. With a self-contained power hammer, you require no external air supply or high-pressure hoses.

The frames are cast iron, like the old Nazel, Beche, and Massey hammers. Cast iron is more expensive to manufacture compared to fabricated hammers but they are heavier, do not flex over time, and have a lifetime warranty on the frame.

Power Hammer for Blacksmith Features

1、Power Forging Hammer does not need an outside air compressor. It will compress air inside with a motor-driven flywheel.

2、The cast Iron Frame will never flex or warp. Compare the weights of different hammers available and you will find that the Anyang Power Hammer is amongst the heaviest. Cast iron is much more expensive to manufacture but allows the designer to put the mass and strength where it is required.

3、Lifetime frame warranty, one year on wearing parts against defects, one year on electrical components against defects.

4、External drive belts. The design keeps the belts dry and away from oil. This eliminates belt slippage and extends belt life. Replacing the belts is quick and easy.

5、The air ports are cast into the hammer. This eliminates internal rubber hoses and fittings.

6、Low maintenance. Anyang power hammer Automatic and fully adjustable oil system. The two grease zerks are easy to reach. Large tapered roller bearings in the crankcase for a long trouble-free life.

7、Simplistic design. Only 3 basic sections (crankcase, compressor piston, ram). Hammers can be disassembled, and if needed rebuilt in a day or less.

8、Simplistic design. Only 3 basic sections (crank case, compressor piston, ram). Hammers can be disassembled, and if needed rebuilt in a day or less.

9、Very controllable, making the use of tooling easy. The operator can change tooling or material thicknesses without adjusting the ram or stroke.

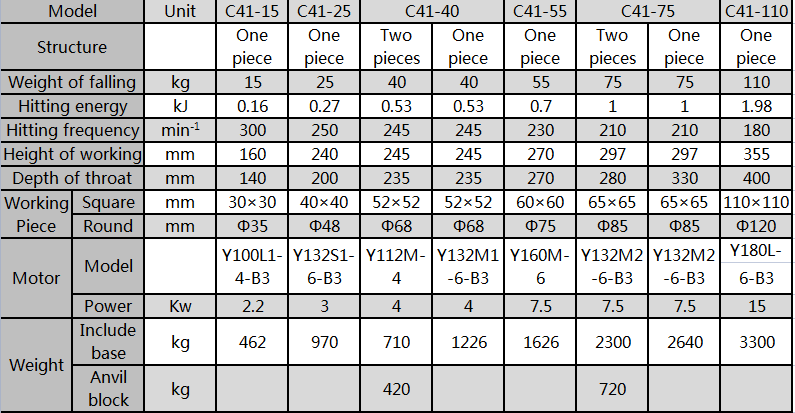

10、Easy to install- once the hammer is uncrated installation takes about 30-45 minutes.Anyang Blacksmith power hammer (C41-15,C41-25,C41-40,C41-55,C41-75,C41-110 ) one piece which makes for easy installation.

11、Anyang power hammer good for making work handling tools for forging operation forged hunting knives, scissors, general operational tools, farm implements and iron art parts for house gate & fence.

12、All Anyang power hammers have got CE. The design is safe.

.png)