There are many kinds of scrap metals in life, good and bad in different sizes. It is a big problem in storage, transportation and smelting in steel mill furnaces. Moreover, the long-term retention of scrap metals will cause mild air pollution, and long-term storage will cause Occupying space can create a physical hazard. We have many ways to dispose of scrap metal, because scrap metal is a reproducible resource, reprocessing can produce new steel, put it into the market again, and recycle it, which can save a lot of resource mining and maintain the earth's mine resources The phenomenon of collapse and lack of random mining. The metal scrap baler produced by Henan Jinzhen Equipmemt Co., Ltd can pack all kinds of scrap metal into lump iron for storage, transportation and smelting.

The use of metal scrap baler:

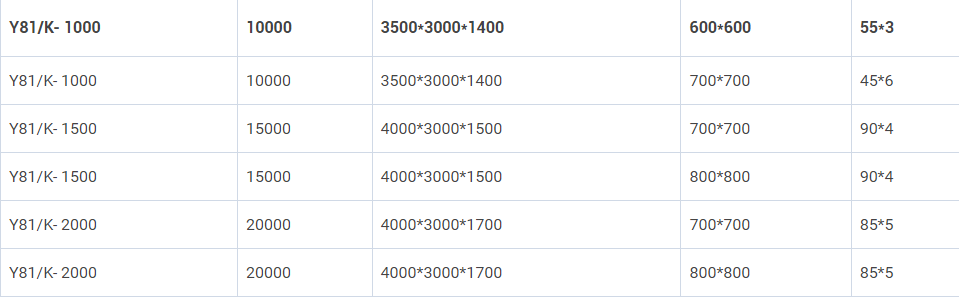

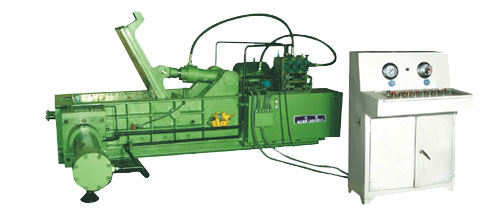

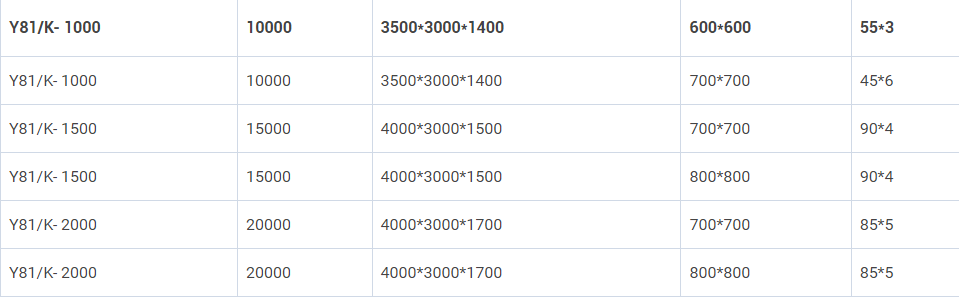

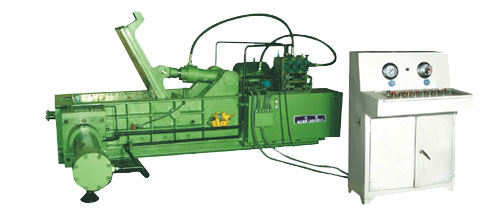

The scrap metal baler can squeeze all kinds of relatively large metal scraps, scrap steel, scrap iron, scrap copper, scrap aluminum, broken car shells, waste oil barrels, etc. into cuboids, cylinders, octagons, etc. . In order to facilitate storage, transportation and furnace recovery for reuse. After being compressed into blocks, it is thrown into the furnace for recycling and the loss of use is extremely low. The entire production process does not require heating, additives or other processes, and it is directly cold-pressed to form, and the original material remains unchanged while forming. For example, cast iron shavings are used instead of cast iron after forming. For castings of special materials, recycling is more meaningful. The metal baler can quickly improve work efficiency, and the packaging is also well guaranteed.

.jpg)

Daily operation specification of metal scrap baler:

1. During use, if the temperature is not enough, adjust the temperature controller (the right hand can raise the temperature, and the left hand can lower the temperature);

2. For the metal baler used in daily use, it must be cleaned regularly and thoroughly. For the metal baler that has not been used for a long time, it must be thoroughly cleaned after the last use is completed, and then stored in a blank place;

3. When packing the goods, the belt length adjuster on the panel must be adjusted according to the size of the goods;

4. The metal baler has an automatic shutdown device, and the shutdown time can be set independently;

5. Special attention should be paid: non-technical personnel cannot disassemble and adjust the use of books at will without explanation, especially when the main body of the baler is painted with red paint.

Henan Jinzhen Equipment Co., Ltd. specializes in providing forging and metallurgical equipment, including ring rolling machines, steel ball skew rolling machines, scrap metal balers, vibrating feeders, etc. The products have been exported to more than 80 countries and regions. We have 20 years of export experience. We have a huge sales system and perfect after-sales service to ensure that every machine that leaves the factory meets the national quality requirements.

.jpg)