After the forging is heated, the air surface temperature is relatively high, usually around 1100°C. At this time, the forging will react with the oxide skin when it contacts with the oxygen in the air, thus forming the product of the oxide scale. During the forging process, the oxide scale It is a dangerous factor for forgings, because the scale will be brought into the workpiece during forging, which will reduce the quality of forgings and cause internal defects.

It is not scary to have a lot of oxide skin on forgings, but what is terrible is that you know that there are so many oxide skins and do not take any measures, and let a product become less beautiful, or even become a waste product in the end, what a pity!

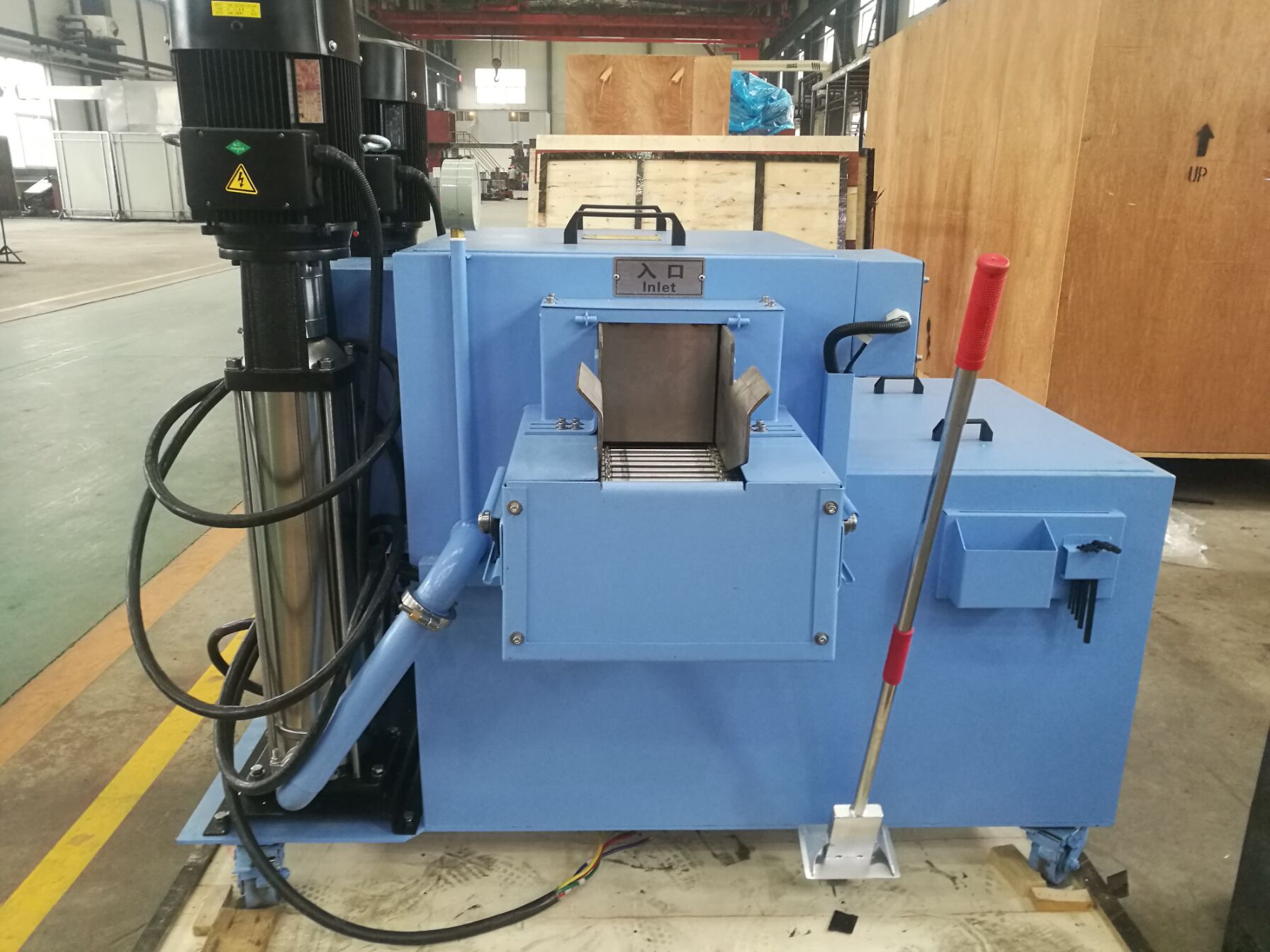

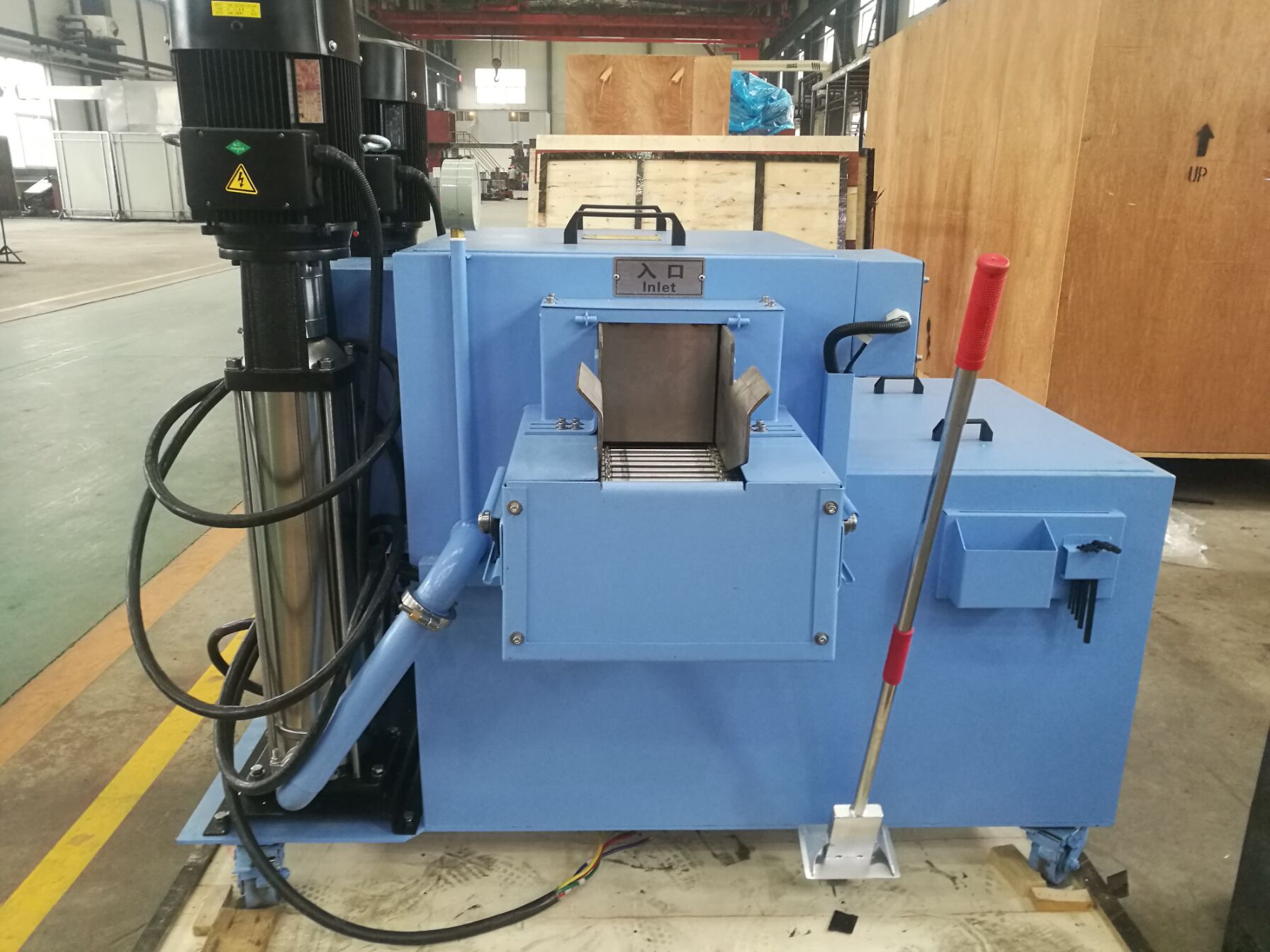

The forging phosphorus removal machine can effectively improve the surface quality of forgings. The forging phosphorus removal machine uses the principle of high-pressure water phosphorus removal to remove the oxide skin on the surface of the forging, so that no oxide skin will fall into the mold during the forging process, and avoid damage to the mold caused by the excessive oxide skin , thereby improving the service life of the mold.

.png)

Generally speaking, the forging descaling process is to remove the oxide scale on the surface of the forging, because the oxide scale on the surface of the forging is of no benefit to the forging, and it will be brought into the forging during the forging process. The inside of the forging is pressed into the "meat" of the forging. It will make the quality of your forgings worse, so we have to use the phosphorus removal process.

Henan Jinzhen Equipment Co., Ltd. specializes in providing forging and metallurgical equipment, including ring rolling machines, steel ball skew rolling machines, scrap metal balers, vibrating feeders, etc. The products have been exported to more than 80 countries and regions. We have 20 years of export experience. We have a huge sales system and perfect after-sales service to ensure that every machine that leaves the factory meets the national quality requirements.

.png)

.png)