The composite process of roll forging-die forging press or die forging hammer is used to produce automobile control arm forgings, with high product dimensional accuracy and good surface quality; compared with the traditional hammer forging process, it can save 17% of raw materials, reduce energy consumption by 60%, and reduce forging costs by 12%, which has significant economic and social benefits.

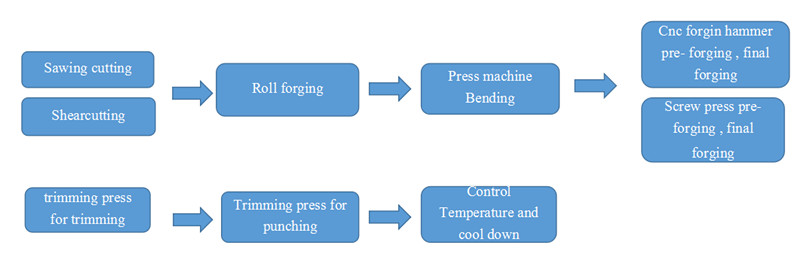

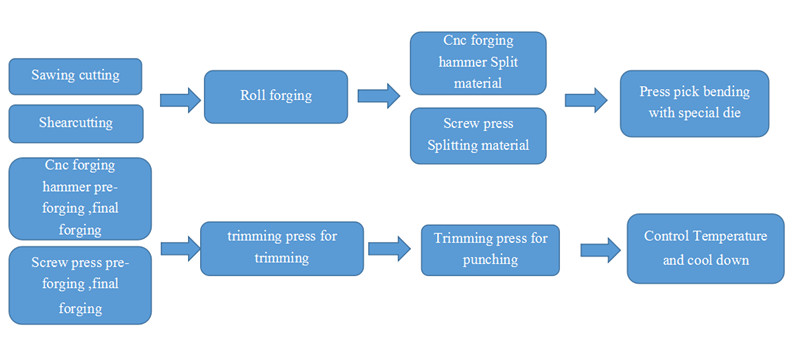

Control arm forging line process

①The first process

②The second process

Advantages of control arm forging production line:

1. If you are interested in this. You can send us drawings and productivity, we can design,The program for you.

2. Before delivery, we can forge the workpiece for you in advance in the factory.

3. Before delivery, you can also come to our factory for inspection.

If you are interested in any forging machine, we can send technical parameters and quotations.